Waste Processing Products

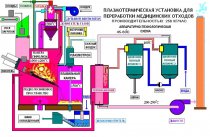

Plasmothermic technology is designed to eliminate any degree of danger from solid industrial and domestic waste. Its application enables the burning components of waste to be burned, moving them into a gas phase and discharging an inorganic part of the waste. The waste gases shall be incinerated in the incinerator ' s vortex and shall be refrigerated and double-staded in the central-pine absorbers. In absorbers, the solution of the calysal clicks, the capture of dust and mild salts of metals. The dust and salts shall be accumulated as a sludge not exceeding 1 per cent of the mass of the waste being processed and then removed for burial or further processing. The purified gas shall be heated to 200 °C and released to the atmosphere. The content of harmful impurities (NOx, SOx, dust, carbon dioxide and furan hydrocarbons) in waste gases does not exceed EEC sanitary standards. The molten inorganic part of the waste is discharged into a water granuller and can be used as a construction material as a stowed chemically inert. Two types of plastic installations have been developed and tested.

Plasmothermic technology is designed to eliminate any degree of danger from solid industrial and domestic waste. Its application enables the burning components of waste to be burned, moving them into a gas phase and discharging an inorganic part of the waste. The waste gases shall be incinerated in the incinerator ' s vortex and shall be refrigerated and double-staded in the central-pine absorbers. In absorbers, the solution of the calysal clicks, the capture of dust and mild salts of metals. The dust and salts shall be accumulated as a sludge not exceeding 1 per cent of the mass of the waste being processed and then removed for burial or further processing. The purified gas shall be heated to 200 °C and released to the atmosphere. The content of harmful impurities (NOx, SOx, dust, carbon dioxide and furan hydrocarbons) in waste gases does not exceed EEC sanitary standards. The molten inorganic part of the waste is discharged into a water granuller and can be used as a construction material as a stowed chemically inert. Two types of plastic installations have been developed and tested.

(a) Plasmothermic installation for disposal of complex morphological and chemical waste.

Technical characteristics of the installation:

Waste production, kg/h 250 Plasmotron installed power, kW 150 Driving air flow, nm3/h 2400 compressed air flow rate, nm3/h, max 100 Waste gas volume, nm3/h 2900

Waste gas temperature, °C

in the melting chamber

1300 - 1500

pyrolysis cell

1050 - 1200

after the incendiary

1,000 - 1100

Electrical unit costs, kWh/kg

0, 6 - 0, 7

Plant area, m2

150

2900

Waste gas temperature, °C

in the melting chamber

1300 - 1500

pyrolysis cell

1050 - 1200

after the incendiary

1,000 - 1100

Electrical unit costs, kWh/kg

0, 6 - 0, 7

Plant area, m2

150

(b) Plasmotermical unit for the alloy of spider-type ash from fire-fighting installations

Plasmotermical unit for the melting of small-scale waste with a capacity of 1 MW (plasmotron vision)Main characteristics of the installation:

Waste production, kg/h 600 Power, MW 1 Temperature, oC in a floating chamber 1350 - 1400 incinerator 1,000 - 1100 Off-gas, nm3/h 1700 Electrical unit costs, kWh/kg 0, 8 - 1 Area occupied, m2 200Technological and economic benefits

- Reduce CO2 emissions;

- Ensure almost 100 per cent of hydrocarbon and carbon combustion;

- Transfer an inorganic part of the waste in one technology cycle into a chemically inert slag;

- Ensure the high environmental safety of waste products. At least 99 per cent of the volume of secondary products corresponds Sanitation standards EEC.

Related posts:

In the Volgograd Region Administration, a concession agreement was signed on public utilities, recycling, disposal (storage) of solid household waste. According…

In the Volgograd Region Administration, a concession agreement was signed on public utilities, recycling, disposal (storage) of solid household waste. According… The building is already over, and a bunch of building debris and waste remains lying, rather than seriously ruining the type of capital. As a result, today the required…

The building is already over, and a bunch of building debris and waste remains lying, rather than seriously ruining the type of capital. As a result, today the required… I ve done a lot of franchise monitors, but I ve got the usual bids, a cafe or a store that s already starting to compete with me, I thought I was bored, telling…

I ve done a lot of franchise monitors, but I ve got the usual bids, a cafe or a store that s already starting to compete with me, I thought I was bored, telling… What are the rules for sorting debris on French Riviera? When we rented an apartment in Paris, there were a few large tanks in the interior courtyard where classic…

What are the rules for sorting debris on French Riviera? When we rented an apartment in Paris, there were a few large tanks in the interior courtyard where classic… Is discipline important in investing? Without any doubt it is true! A disciplined investor will never buy securities without serious analysis or pay attention to…

Is discipline important in investing? Without any doubt it is true! A disciplined investor will never buy securities without serious analysis or pay attention to… Structural debris: brick, brisket, concrete, stoves obtained during the dismantling of construction sites are transformed into a secondary building block on GOST…

Structural debris: brick, brisket, concrete, stoves obtained during the dismantling of construction sites are transformed into a secondary building block on GOST… Professional presentation demands more than just content - it requires the right display platform. The Black Easel stands out as a sophisticated solution for artists…

Professional presentation demands more than just content - it requires the right display platform. The Black Easel stands out as a sophisticated solution for artists… By 2015, equipped reception and recycling facilities should be established in the five administrative districts of Moscow. They ll be set up by private companies…

By 2015, equipped reception and recycling facilities should be established in the five administrative districts of Moscow. They ll be set up by private companies… The Territorial Waste Management Scheme was held by the Parliamentary Hearings at Medoldum Parliamentary hearings of the Regional Waste Management Scheme were held…

The Territorial Waste Management Scheme was held by the Parliamentary Hearings at Medoldum Parliamentary hearings of the Regional Waste Management Scheme were held… Environmentally sound behaviour is very often consistent with the principles of rationality, servitude, prudential treatment of purchases, by their time, to environmental…

Environmentally sound behaviour is very often consistent with the principles of rationality, servitude, prudential treatment of purchases, by their time, to environmental…